AURA HZ

HORIZONTAL LAMINAR FLOW CABINET

A COMPLETE AND USER FRIENDLY TOOL FOR THE PROTECTION OF HIGHLY SENSITIVE PRODUCTS

The internal design, the air flow aerodynamics and monitoring, the special H14 filter with Micromesh downstream equalising plenum, guarantees the highest performances at the most stringent safety levels and operator comfort.

- High efficiency washable polyurethane prefilters

- H14 class HEPA filter

- Electronic control air speed

- Working surface in stainless-steel

- Side panels in tempered glass

- Micromesh membrane on HEPA filter downstream surface for perfect airspeed distribution

- Up to four plugs installable near the light on the ceiling of the cabinet to leave working surface free

- Sizes: 1.2, 1.8

AURA SDV

VERTICAL LAMINAR FLOW CABINET

This full sized 1.2 m cabinet provides plenty of room to work with sensitive products in a clean environment.

- Electrically operated front glass

- Tight seal closure system

- White painted steel working area to increase lighting

- Stainless-steel working surface

- Sizes: 1.2

AURA MINI

VERTICAL LAMINAR FLOW CABINET

WHEN SPACE MATTERS

This compact benchtop laminar flow cabinets provide all you need to keep your products clean and protected without taking away your lab space.

- Centrifugal Motorblower with digital inverter for optimal performance

- Elapsed time-meter

- Exhaust filter

- Removable perforated work surface and back wall of the work chamber made of AISI 304 stainless steel

- Cabinet outer surfaces made of cold rolled steel with paint finish

- Front and side panels in 5mm thick tempered glass

- H14 class HEPA

- Exhaust filter (or pre-filter) type Filtrete® with a gravimetric efficiency higher than 99% on 3 μm particles

- Optional cover with UV light (includes safety switch to turn off UV if cover is removed from the cabinet)

- Dual operation system

INWARD air barrier. In this configuration an air barrier flows through the front opening and is recirculated with the downflow air by a motor blower. 70% of the air is returned to the work area through the main HEPA filter and 30% is exhausted into the environment through a Filtrete® exhaust filter with gravimetric efficiency of 99% on 3 μm particles. In this configuration an excellent product protection is ensured, as well as an outstanding

containment.

OUTWARD air barrier. In this case the air is sucked through the Filtrete® prefilter, mixed with the incoming recirculating air and then filtered through the main HEPA filter into the work area: here 30% of the air is exhausted through the front opening and 70% is recirculated. This configuration ensures the highest product protection. In the OUTWARD configuration this unit can easily be used as an “active PCR” cabinet for DNA carry over blocking.

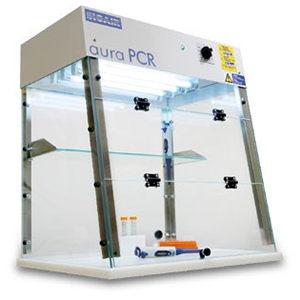

AURA PCR

DNA CROSS-CONTAMINATION CONTROL ENCLOSURE

These state-of-the-art PCR cabinets are specially designed for preamplification sample preparation in controlled environment in order to prevent DNA carry-over. Any aerosol generated during the handling of the post amplification samples cannot enter the cupboard; any molecule of DNA herein contained is subsequently neutralised with the help of UV radiations.

- Passive PCR enclosure (non ventilated)

- Fluorescent light turns on automatically when opening the front glass or when UV lights turn off (user selectable)

- Digital timer for UV lights with memory of the last setpoint

- 100% UV-safe

- Front glass divided in three hinged sectors

- Internal foldable shelf in glass

- Working surface in chemical resistant polyethylene

- Working area walls in tempered glass 6 mm thick